Contact us

Helen Xu

Sales Manager

Mobile/WeChat: +0086 18679102530

Skype: 792094854@qq.com

E-mail: helen@sdstripsteel.com

Let’s learn about spring steel together!

This kind of spring (such as No. 65, No. 70 steel, etc.) has the advantages of low cost and convenient source of raw materials. The disadvantage is that the elastic limit is low and it is easy to lose elasticity after repeated deformation. It cannot be cut at temperatures below 130 degrees. environment to work normally.

keyword:

2024-04-30

The purpose of steel heat treatment

The manufacturing process of pressure vessels and pipelines will bring about the following problems: cold work hardening caused by excessive cold rolling, cold shaping and other cold processing;

keyword:

2024-04-30

Principles of heat treatment of steel

The purpose of heat treatment is to change the internal structure of steel to improve the performance of the steel. Appropriate heat treatment can significantly improve the mechanical properties of steel and extend the service life of machine parts. The heat treatment process can not only strengthen metal materials, fully tap the performance potential of materials, reduce structural weight, save energy and energy, but also improve the quality of mechanical products and greatly extend the service life of machine parts.

keyword:

2024-04-30

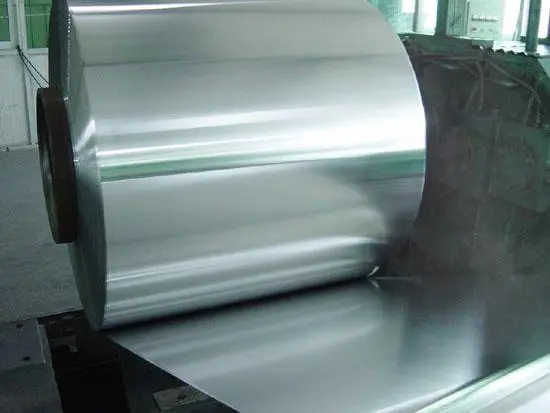

Cold rolled strip classification

Black annealed strip: Cold-rolled strip is directly heated to the annealing temperature, and the surface color turns black due to high temperature exposure to air. The physical properties become softer, and it is generally used for deep processing of steel strips such as re-rolling, stamping, and large deformation.

keyword:

2024-04-30

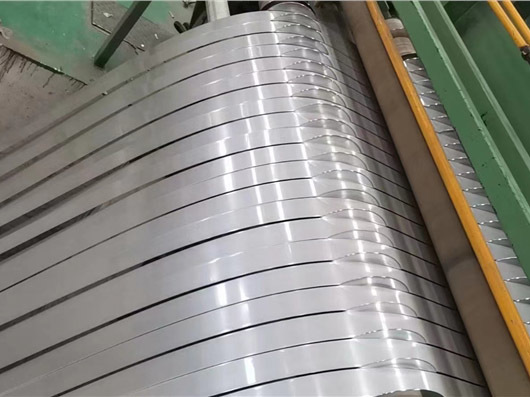

The difference between hot rolled strip and cold rolled strip

Due to a certain degree of work hardening, cold-rolled steel plates have low toughness, but can achieve a good yield-to-strength ratio and are used to cold-bend spring sheets and other parts. At the same time, because the yield point is closer to the tensile strength, so during use There is no foresight of danger, and accidents are likely to occur when the load exceeds the allowable load.

keyword:

2024-04-30

Defects in heat treatment of stainless steel strips

Gas corrosion is a small black spot-like pit on the surface of the strip steel. If the emulsion, oil, salt, dirt and other residues on the surface of the strip are not removed, part of the surface or the entire surface of the strip (if it stays in the furnace for a long time) will be corroded by the gas. At high temperatures, gas corrosion on the surface of strip steel is more serious.

keyword:

2024-04-30

What are the materials of steel strips?

The steel belt materials mainly include carbon steel belt, stainless steel belt, electrical steel belt, aluminum alloy steel belt, etc. The details are as follows:

keyword:

2024-04-30

What are the types of heat treatments for steel?

Quenching + high-temperature tempering (also called quenching and tempering treatment) heats the steel pipe to the quenching temperature to transform the internal structure of the steel pipe into austenite, and then rapidly cools it at a speed greater than the critical quenching speed to transform the internal structure of the steel pipe into martensite. Coupled with high-temperature tempering, the steel pipe structure is finally transformed into a uniform tempered troostite structure.

keyword:

2024-04-30

What are the methods of heat treatment of steel?

The main heat treatment methods of steel are as follows: Quenching. A heat treatment process in which steel is heated to a certain temperature above the critical point Ac3 or Ac1, and then cooled at a rate greater than the critical cooling rate to obtain martensite (or lower bainite) after heat preservation. Its purpose is to greatly increase the hardness of steel. annealing.

keyword:

2024-04-30

Principles of heat treatment of steel

The purpose of heat treatment is to change the internal structure of steel to improve the performance of the steel. Appropriate heat treatment can significantly improve the mechanical properties of steel and extend the service life of machine parts. The heat treatment process can not only strengthen metal materials, fully tap the performance potential of materials, reduce structural weight, save energy and energy, but also improve the quality of mechanical products and greatly extend the service life of machine parts.

keyword:

2024-04-30